Sensational Tips About How To Build A Vacuum Table

If you dont have access to a lathe, you could cut a ring out of mdf the same size as your vacuum nozzle and bond that to the vacuum table.

How to build a vacuum table. Bill teaches you how to make your very own large vacuum former usin. The hold down table is a wooden box with a grid of small holes on the top with a larger ho. In this video i will make a vacuum hold down table for my cnc and it actually worked….

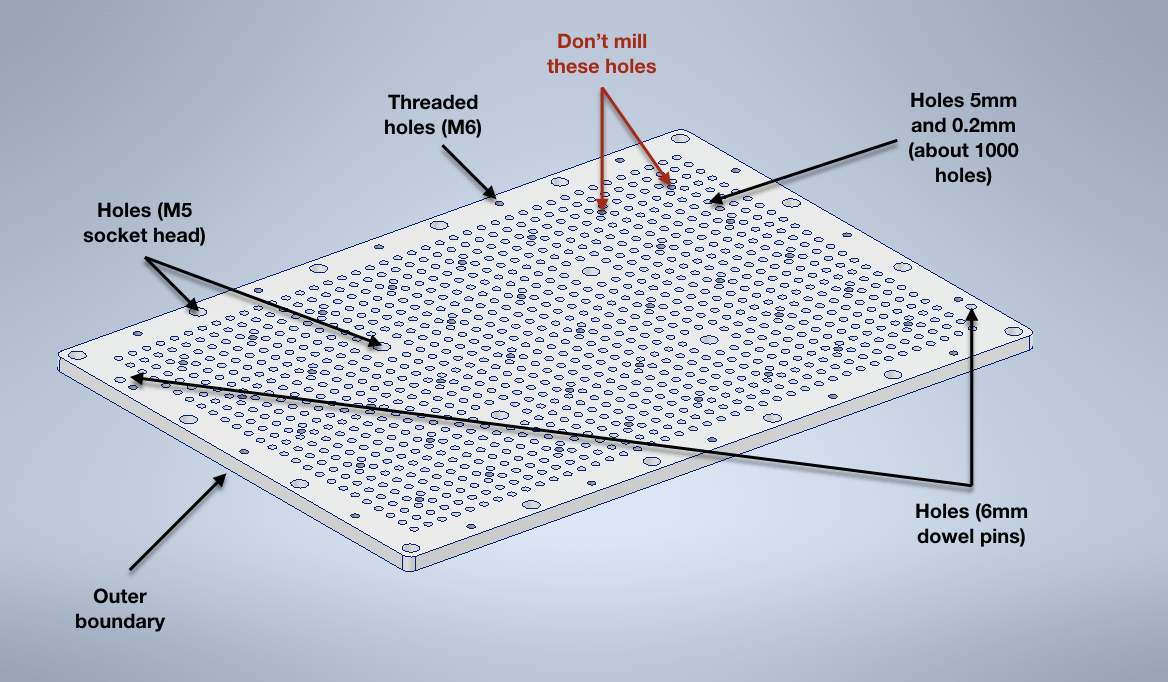

Placing the frame and the plastic over a mould. The vacuum forming process involves: 1 × sheet of aluminium for base plate 460mm x 310mm (at least 20mm thick) 1 × sheet of aluminium for top plate 460mm x 310mm (at least 9mm thick) 3 × g 1/8 to 12mm.

Not having a vacuum table. Specialy aluminium anodized electronic control plates for riverboats. Heating the plastic sheet until it becomes soft.

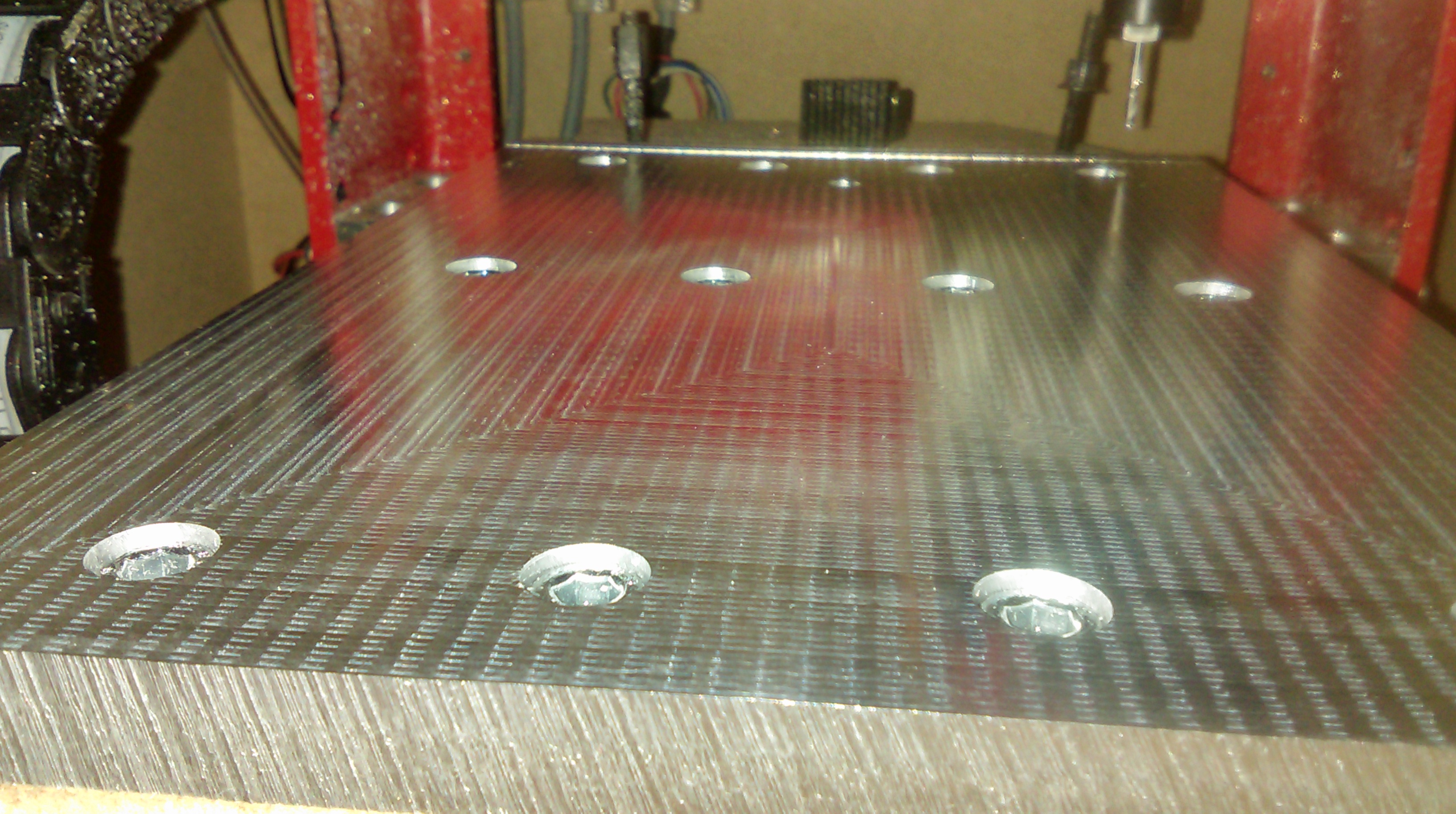

It is better to have lots of little air. I have made a portable vacuum hold down table for the cnc router. Machining a vacuum table for a specific kind of work.

These two spoilboard options give me tons of flexibili. Cut your metal sheet to size and mark out where you want the air holes to be. How to build a vacuum table for screenprinting?

This vacuum table project was just an experiment to see if a design like. The hoover nozzle connects in to the. Alternatively you can purchase similar flanged inlet.